Assess. Engineer. Innovate.

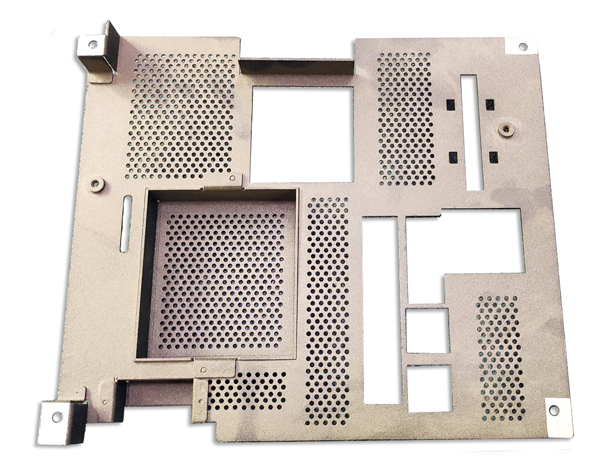

From fully automated sheet metal stamping, fabrication and die casting to CNC prototyping, metal spinning, tooling and metal extrusion – Airspeed provide a full spectrum of metal manufacturing processes. Polishing, painting, plating and many other surface treatments available. Please contact us with your specific requirements.

9 CNC lathes and 18 manual lathes, up to 42" diameter capability.

Secondary processes include stamping presses, powder coat paint line with manual and automatic spray wet-coat

Engineered solutions for your business.

Contact us to see how we can help you assess, engineer and innovate today.

Corporate Headquarters

Airspeed LLC

1413 South 3rd Street Ext

Mebane, NC 27302

USA

![]() +1 919 644 1222

+1 919 644 1222